CHAUNCEY, Ohio — As it builds homes for the Survivor Advocacy Outreach Program in Chauncey, Vitruvian also is training students, people aging out of foster care, and former bricklayers in the 3D-printed construction industry.

“There’s a lot of interest in industry coming in and building here and creating jobs here. But there’s a delta between what’s available,” Vitruvian founder Chris Sentz told the Independent in an interview. “It’s all training, getting robotics technicians, getting people who can work in manufacturing and have any experience or training in that. The more that we can empower this population and educate, the stronger this area is going to be.”

Vitruvian offers a state-certified digital masonry program in collaboration with the International Union of Bricklayers and Allied Craftworkers Local 23, Sentz said.

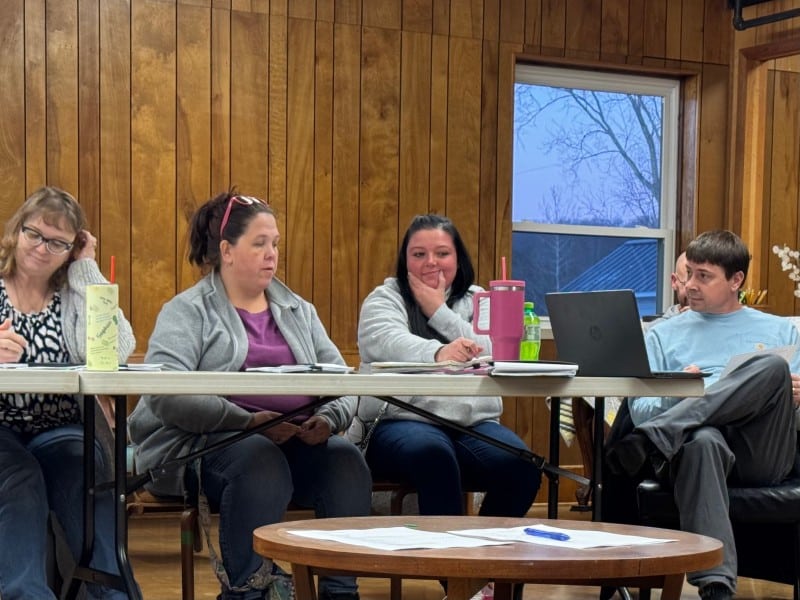

Southeast Ohio Central Labor Council AFL-CIO President Ted Linscott, also a former bricklayer, coordinated the union’s partnership with Vitruvian.

“We’ve got to stay on top of any kind of new, emerging technology that has to do with the structural masonry of a building, whether it’s a home, commercial building or anything like that,” said Linscott. “If you say ‘no, that’s just going to be a fad, it’ll go away,’ then you might get left out and get left behind.”

Vitruvian has already trained 23 adults through the program since it launched this summer. Currently, Vitruvian is working with 27 students at New Lexington City School District, with visions of eventually supporting a pre-apprenticeship program in all area schools.

“If they go through a pre-apprenticeship program that’s recognized by the unions, they can enter an apprenticeship,” Sentz said. “That’s zero debt; that’s a ticket into the middle class.”

Survivor Advocacy Outreach Program Executive Director Madison Trace said the program will allow students, SAOP clients, and other local people opportunities for good jobs.

“Chris is just bringing a really new, innovative, fun technology, but he’s brought so much more than just building homes to this area,” said Trace.

Currently working with Vitruvian through the bricklayers union are a journeyman and an apprentice, Linscott said.

Hannah Miller, a journeyman affiliated with the bricklayers who completed Vitruvian’s pre-apprenticeship program, was working on the Chauncey build during the Independent’s tour of the site. Miller got her position with Vitruvian after being laid off from a more traditional construction job, through the union’s partnership with the bricklayers.

“I just came and did some training when I was laid off, and ended up being able to go right on the job site,” Miller said.

“In the more traditional side of things, things have slowed down, and so the bricklayers union will go out, and we’re looking for any work we can get pretty much,” Miller said.

Miller added that work at Vitruvian is “very different. But I think, you know, it could be a step forward.”

Specifically, Miller said there’s a learning curve involved to working with the 3D printers.

“You’re preparing for the printing, you’re cleaning up after the printing, you’re monitoring things to make sure that the consistency of the concrete is correct,” Miller said.

If 3D-printed construction takes off as the new norm, “I’d be open to making this ultimately my career,” Miller said. “It’s a lot easier physically.”

Pre-apprenticeship participant Malachi Jenkins was also working at the Chauncey home build when the Independent toured the site on Oct. 1. Jenkins recently aged out of foster care and secured a position in the pre-apprenticeship program through Vitruvian’s partnership with the Logan-based nonprofit Foster Hub, designed to support people who age out of foster care.

“It’s been a great experience, learning a lot of stuff,” Jenkins said. “It’s everything I like — working outside, getting my hands dirty. That’s how I’ve always been. So it’s just something I really enjoy.

Sentz acknowledged in an interview with the Independent that the advent of 3D-printed construction reduces the requisite number of construction jobs — but he argued that’s a good thing, because the supply of open positions in the industry currently outstrips supply.

As of early 2025, industry models and experts estimated that 439,000 additional construction jobs would be needed to meet demand, and that the U.S. wasn’t training enough construction workers to keep pace with retirees. However, a more recent report said that the industry saw a nearly 10-year low in open construction jobs at the end of August, though many jobs were still open.

“It’s not going to take away any jobs, because we don’t have enough people doing the

work to begin with,” said Eric Wooldridge. Wooldridge directs the Kentucky Community & Technical College System’s Additive Manufacturing Center, which works directly on 3D-printing technology in Appalachia. He also did consulting work for the Chauncey project through his private business.

“The printer is just taking care of the wall structure,” Wooldridge added. “Your internal finishes, your plaster work, your concrete foundation, your excavators, all that’s still got to be done … but it does allow for a more efficient and safer and more precise process.”

Linscott said he hopes workers from traditional construction can continue to be involved as the industry progresses. “Why can’t we be training our people to do that kind of work?” he said.

Sentz says 3D-printed construction will be able to attract more young people than traditional construction.

“We’ll go and say, ‘Who wants to play with this robot?’ Who doesn’t want to play with a giant robot?” Sentz said. “And so then we can say, ‘Hey, listen, you can get the best of both worlds. You can work with your hands, you can be on site. You can go no-debt. You get paid to train for two years as an apprentice and then make journeyman wages and have the protection of a union. Or you can be an independent contractor.’ But that’s a career path that a lot of folks don’t know exists. It is a very viable, very fruitful career.”

Let us know what's happening in your neck of the woods!

Get in touch and share a story!